Industrial Sharpening & Manufacturing Services

Your End-to-End Blade Solutions Provider

At Valley Grinding, we know downtime costs you. That’s why we offer total blade management—from custom manufacturing and sharpening to repairs and inventory support. Count on us to keep your production moving.

Industrial Blade Sharpening & Grinding You Can Rely On

Precision, reliability and uptime are everything on your production floor. For nearly four decades, we’ve been a trusted partner to manufacturers across industries, delivering expert industrial blade sharpening, die sharpening, precision grinding and comprehensive tool management solutions that keep your operations running sharper, faster and safer. From routine maintenance to complex rebuilds, our team brings deep product knowledge and a commitment to quality that helps you reduce downtime, extend tool life, and optimize performance.

Our full suite of services, including expedited FasTrack sharpening, knife holder rebuilds, nationwide pickup and delivery, and customized slitter management programs, is designed to simplify your workflow and support your production goals. Whether you’re sharpening industrial cutters, managing blade inventory or training your team on best practices, Valley Grinding provides dependable solutions backed by real people, real service and results you can count on.

Valley Grinding Services

Frequently Asked Questions

Blade Sharpening

Get same- or next-day service for urgent needs, with standard turnaround in three business days.

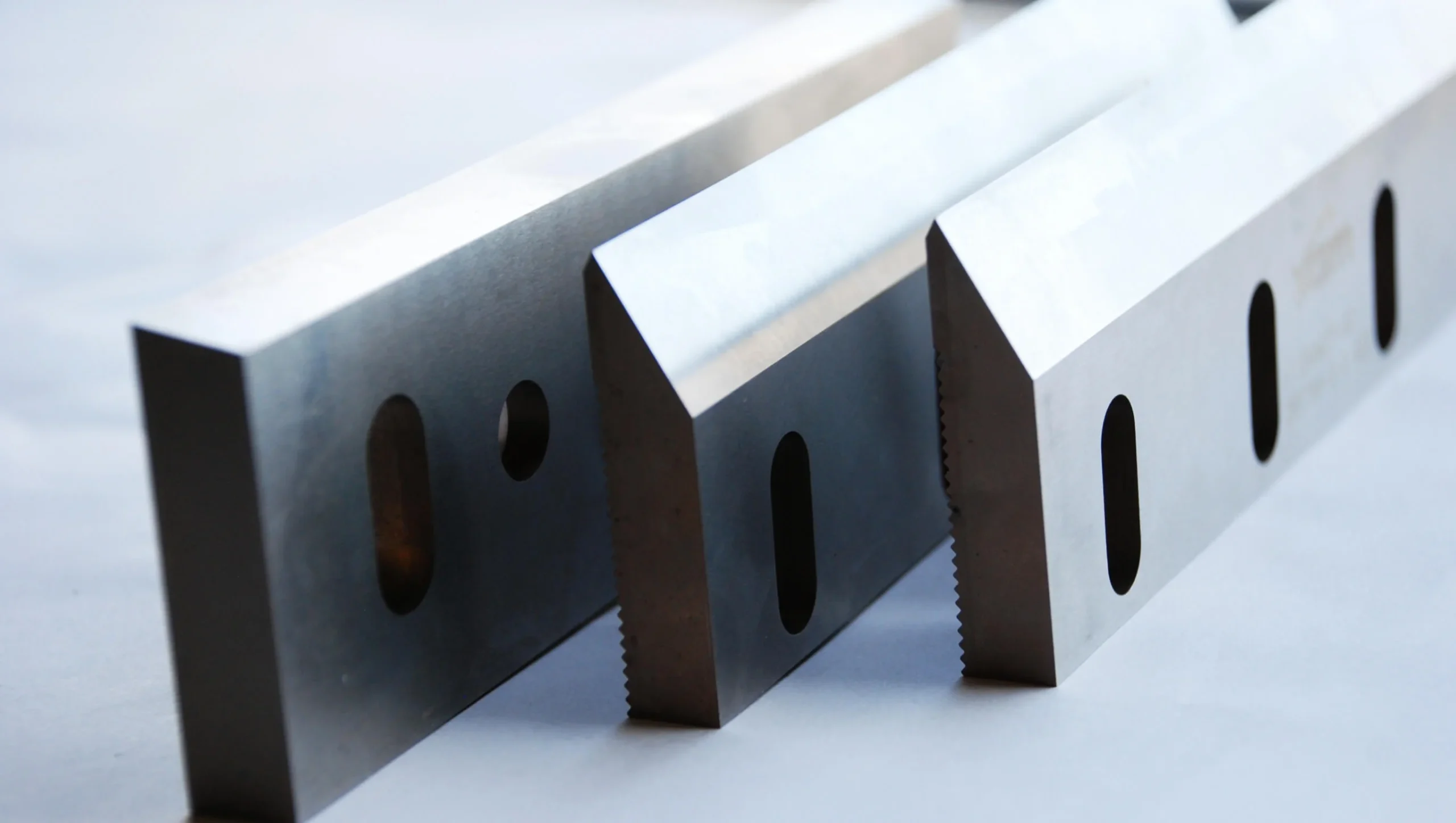

Granulator blades, punch dies, slitters and trim choppers—we’ll customize to your specs and substrates.

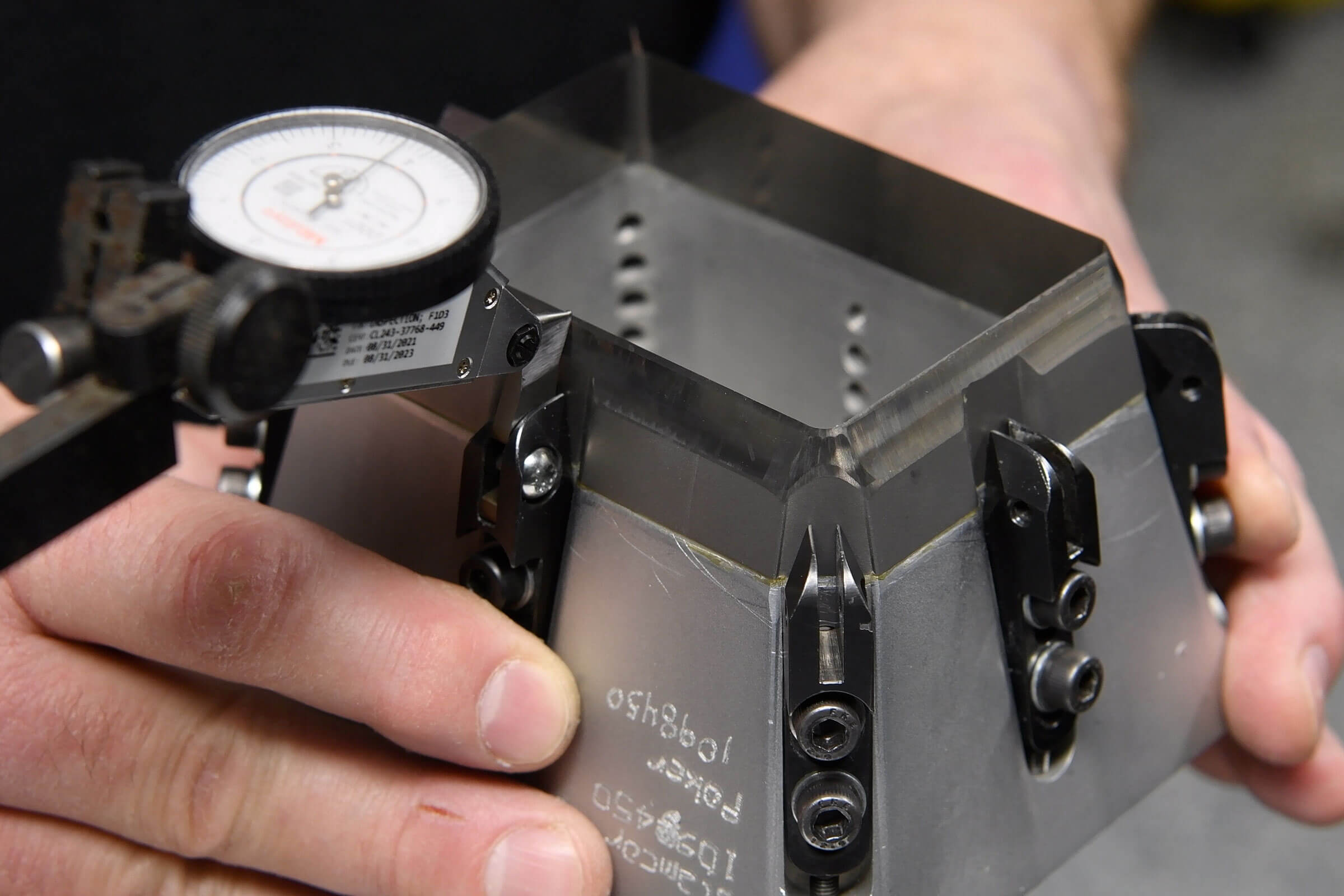

Die Sharpening

Yes, we provide both, along with knife holder repairs and blade optimization to meet OEM standards

As the exclusive Stamfag USA partner, we ship premium dies in just 3–5 business days.

Slitter Management

Monthly pricing, flexible pickup/delivery, blade performance monitoring and expert training.

Absolutely. We offer on-site consultations to prep your team for peak performance.

Contract Manufacturing

No problem—we’ll reverse engineer your part quickly and accurately.

We work with various grades and offer turning, milling, grinding, honing, lapping and laser etching.

Trim Chopper Rebuilds

We inspect, sharpen, replace worn parts and recalibrate systems to factory specs—testing with your product samples.

Timelines vary, but we prioritize fast turnaround to minimize downtime.

Reach Out Today

From initial concept through production, we partner with OEMs who value precision and consistency. Our experienced team is ready to support custom requirements and scalable manufacturing needs. Reach out today to explore how we can collaborate.