SLASH YOUR DOWNTIME

MAXIMIZE YOUR EFFICIENCY.

PERFORM AT TOP-TIER CAPACITY — WITH ZERO GUESSWORK

Pinpoint the reasons why your operations aren't running at full productivity with an equipment and usage audit.

Schedule a free consultation to learn how our comprehensive audit — and customized solutions — can boost your profits every quarter.

3 STEP PROCESS FOR SUCCESS

Our comprehensive operations audit is packed with valuable insights and solutions and is offered to new Slitter Management Program clients free of charge.

Free

Consultation

We'll talk about the problems you're dealing with and how we can help — with no pressure to work with us. The cost and scope of the audit will be determined at this time.

Comprehensive Audit and Solutions

We conduct an in-depth review of your knife holders, tolerances, alignment, cut quality, speed, dust, adhesive buildup, and more. We'll recommend whether to optimize, repair, or fully replace your setup — we'll even handle the installation.

Custom Slitter Management Program

Take advantage of our custom slitter management program that fits your budget and needs.

If you start a program with us, the comprehensive audit is free of charge.

SLITTER MANAGEMENT PROGRAM FEATURES

Customizable and cost-effective, our Slitter Management Program brings a strategic advantage to paper mills and converting facilities. We design a custom program around your requirements and budget.

Expert Operator Training

We provide operator training on tangential cutting, machine setup, and best practices, such as the principles of shear slitting, how the slitter section is designed to work, and what to look for in upset conditions to correct the clit edge.

Access a full training guide on the principles of shear slitting to learn more.

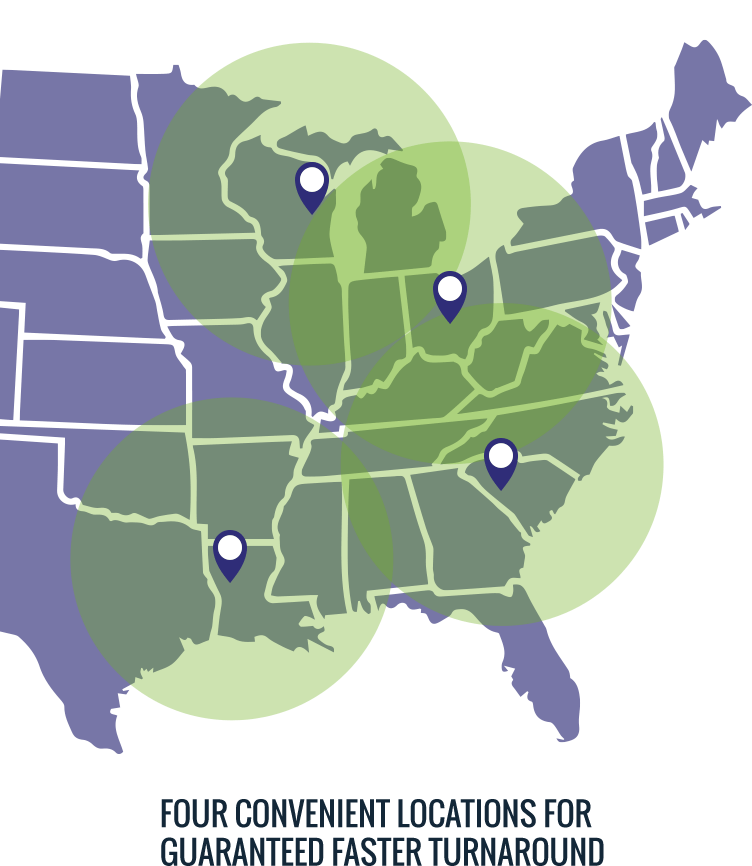

Pickup and Delivery Service

Operating out of four regional locations (WI, OH, SC, and LA), we pick up and deliver your blades in our custom aluminum or wood shipping boxes with our own vehicles, keeping your assets safe to and from our service centers. This system also improves organization and asset tracking at the machine.

Blade Replacement and Grinding

High-quality sharpening and slitter replacement services using manufactured best-in-class A11 and carbide slitting tools made from U.S. steel in Little Chute, Wisconsin. We also manufacture our own super-finisher sharpening machines to ensure the most consistent, high-polished, keenest edges in the industry. What's more, your slitter blades receive a protective edge coating to help ensure product and employee safety.

Predictable Monthly Billing

Fixed, easy-to-budget payments with 1-, 2-, or 3-year contract options.

Vendor Managed Inventory

Never worry about in-house tracking of slitter blade inventory. Our automated replenishment keeps you running without delays.

Customized to Your Needs

Choose from a full suite of services, including winder shutdown assistance, inventory management, and slitter section upgrades.

Slitter System Evaluations and Audits

Identify issues like excessive runout early to prevent costly downtime and reduce how often knives require sharpening.

Winder Shutdown Assistance

Get slitter section audits/mechanical inspection of the slitter section with an accompanying report, as well as product installation (Valley Grinding super-finished knives), if requested.

The Manufacturer Advantage: Better Pricing, Stronger Support

As a manufacturer and service provider, you get access to 52 OEMs for unparalleled technical support, as well as competitive pricing without third-party markups.