Industrial Knife Holder Rebuilds

- Inspection, Lubrication and Replacement

- Knife Holder Refurbish and Repair

- Meets Major OEM Specifications

INDUSTRIAL KNIFE HOLDER REBUILDS

The industrial knife holder consists of two major components, each critical to efficient industrial sharpening. The control body connects the holder to the dovetail, and the blade cartridge holds the top slitter knife.

We service a range of OEMs, including:

Each of our holder rebuilds includes inspection, lubrication and replacement of the standard wear parts. These wear parts can be sent back to the customer upon request. Any additional parts that are worn, and need to be replaced, are serviced on a time and material basis.

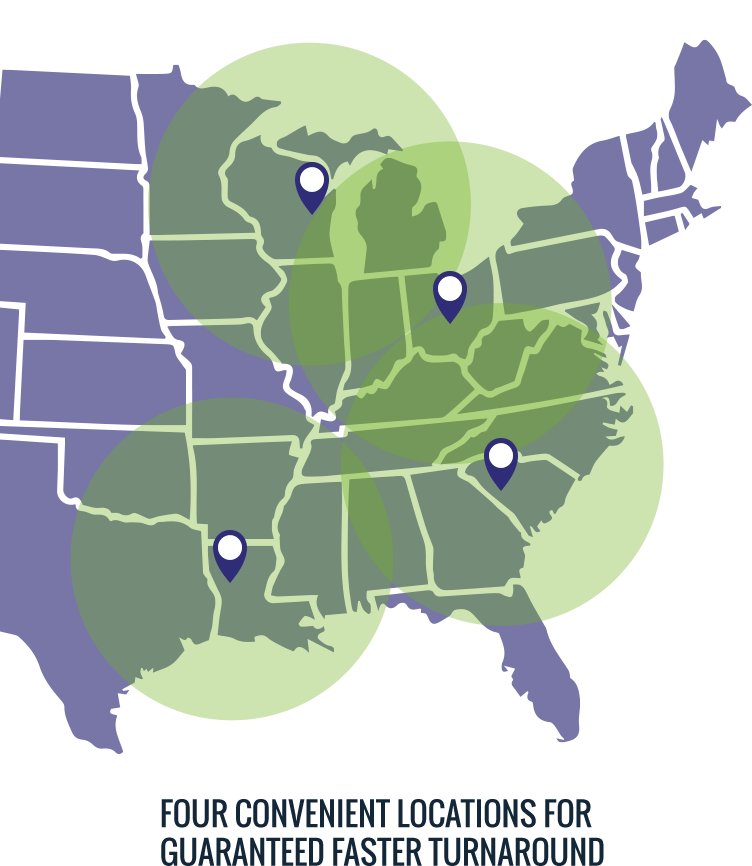

Typical turnaround time for knife holder refurbishment is approximately 1-2 weeks, but expedited services are available.

INDUSTRIAL KNIFE SHARPENING & REBUILDING WITH YOU IN MIND

We care about our customers' bottom line! If the cost of a holder rebuild reaches more than 50 percent of the cost of a new knife holder, Valley Grinding & Manufacturing will notify you. On the basis of your responses and needs, we will either bill you for the work completed and return the holder knife, or we will complete a full holder rebuild.

An industrial knife holder rebuild is a critical application that requires precise units that meet OEM specifications. Our holder rebuild service offers the precision, experience and expertise your business needs for optimal performance, with the outstanding customer service you expect from Valley Grinding & Manufacturing.

We're Ready To Help

Fill out this short form and a Valley Grinding & Manufacturing representative will contact you by the next business day. If you need immediate assistance, please call (800) 950-7675. Need parts? buy easily at our online store: advantedgesupply.com.