TOTANI

BLADES & SHARPENING SERVICES

TOTANI

- Operator training

- Three-day or better in-house grinding

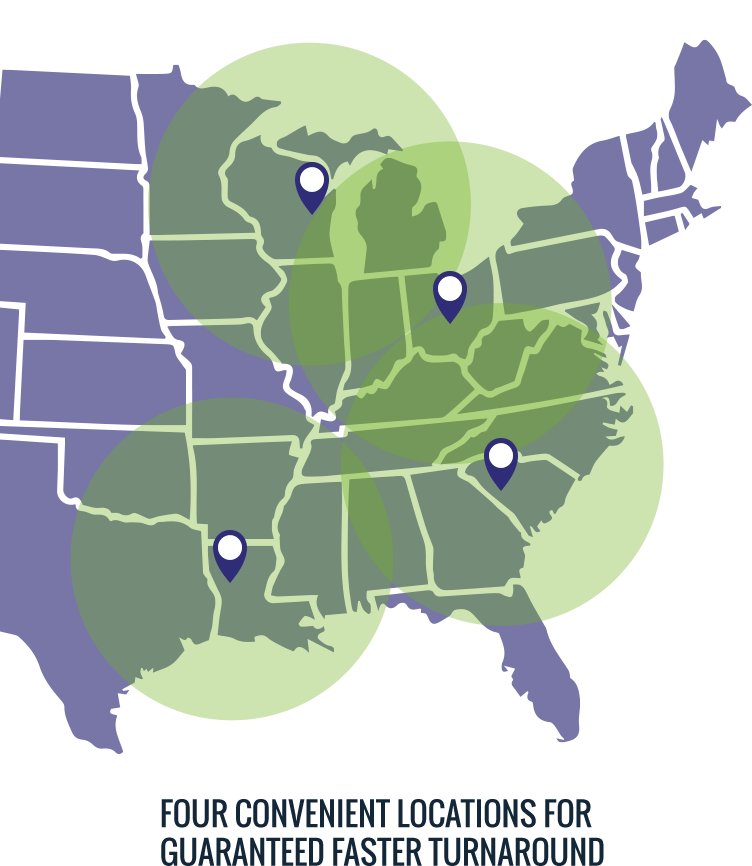

- Pickup and delivery throughout the United States

- Slitter management programs

- FasTrack service availability

- Precision inspection and quality guarantee with Micro-Vu, surface finish and hardness testing

Consumer safety with clean production

Plastic bag and pouch making often requires extra attention to a clean and sterile manufacturing process. Since these packaging products are often used in food and medical applications, we pay close attention to the specifications required for food-grade blades, made out of powdered metal or heat-treated stainless steel.

INNOVATING WITH YOU

Totani’s U.S. headquarters is less than 15 miles from our corporate office, which gives us a unique perspective on their products and how to get the most precise cuts for your specifications. This relationship has also resulted in some unique innovations with Totani products.

Partnering with Tonani, our research and development team tested seal cutters for cross web cutting in order to increase wear resistance. The resulting titanium nitrate coating innovation dramatically improved run times and quality of packaging product cuts.

INDUSTRIES

Industries that can particularly benefit from our experience with Totani products include:

- Food

- Stand-up, hot-fill, side-gusset, box and zipper packaging for candy, sugar, wheat, retort foods, frozen foods, fruit and beverages

- Medical

- Packaging for polyethylene gloves and first aid kits

- Household/Health and beauty

- Refill pouches for soaps and fabric softener

- Plastic bags

- Garbage bags

- Pet food

- Lawn and garden

- Seeds and fertilizer

Contact us and one of our technical experts can talk with you about how to maximize process efficiency and profitability.